What Coating is on My Paper-like Screen Protector?

Catalog

1. What is coating technology?

2. What are coating technical difficulties?

3. What does “A” mean?

4. What Related Products are on the Market?Steps for proper installation

5. What are the Upgrades of AR Compared to 3A ?

6. Conclusion

*This article contain 2405 words, estimated cost 8-12 minutes to read.

Introduction

What coating is on my paper texture screen protector? The product description says that this film has anti-glare, how does it do that? In this article, we will go through the lies of many merchants on the market and explore how the coatings on a paper-like film are formed. What functions those coating layers play? What happens when they are put together? and which paper-like film with which coating is more worthy of our choice?

Conclusion First: AR coating is the latest technology. It structurally solved the problem of coating overlay, which means you can enjoy multiple practical functions in one film.

Protescreen AR+ iPad Paper Texture Screen Protectorn Protector

1. What is Screen Protector Coating Technology?

Paper texture film coating technology generally refers to a special material layer coated on a substrate such as PET & PETE (polyethylene terephthalate) It aim to improve surface properties such as feel, friction coefficient, reflectivity, etc. Paper texture screen protector simulate the writing and drawing experience of real paper. These coating layers can contain a variety of ingredients, such as polymers and nanoparticles to provide the desired functions and performance.

Materials including but not limited to: Wear-resistant layer slurry; Hardening layer coating liquid; Nanocellulose, polyvinyl alcohol (PVA), polyhydroxybutyrate (PHB), polylactic acid (PLA), and starch; Polysaccharide polymer coatings; etc.

* Protescreen Lab

2. What are Coating Technical Difficulties?

The difficulties of superimposing multiple coatings on paper-like films mainly lie in the mutual influence between coatings, the adhesion between coatings and substrates, the uniformity of coatings, and the durability of coatings. The following are the principles and explanations of these difficulties:

- Interaction between coatings: The chemical and physical properties of different coating materials may affect each other, resulting in a decrease in coating performance. For example, some coating materials may react chemically with the substrate, affecting the stability and durability of the coating.

- Adhesion between coating and substrate: The coating needs good adhesion to the substrate (such as PET film) to ensure that the coating is not easy to fall off. If the adhesion is insufficient, the coating may peel off during use, affecting the service life of the product.

- Uniformity of coating: Maintaining the uniformity of the coating is a challenge during the multi-layer coating process. The thickness and uniformity of the coating directly affect the optical properties and barrier properties of the product. Uneven coatings may cause glare, blurring, and other problems.

- Durability of coating: Paper-like films are affected by factors such as friction and temperature changes during use, so the coating needs to have good durability. Coatings with insufficient durability may wear out over time and lose their original functions.

- Selection of coating materials: Selecting suitable coating materials to achieve the desired functions (such as anti-glare, waterproof, oil-proof, etc.) is another difficulty. Different coating materials may require different processing processes, which increases the complexity of the production process.

- Environmental protection and sustainability: With the improvement of environmental awareness, it has become a challenge to develop degradable or recyclable coating materials. This requires coating materials to not only meet functional requirements but also meet environmental protection and sustainability requirements.

- Precise control of the coating process: Precise control of coating, including coating thickness, uniformity, and adhesion, requires high-precision equipment and processes. This may involve complex process parameter adjustment and optimization.

In summary, the difficulties of superimposing multiple coatings on paper-like films involve multiple aspects such as material selection, coating process, environmental protection, and product performance, and these challenges need to be overcome through cross-research in materials science, chemical engineering, and surface science.

3. What Does “A” Mean?

In the naming of the paper texture screen protector, "A" represents the specific functional properties of a functional coating layer. For instance, anti-glare coating, anti-fingerprint coating, anti-scratch coating, etc. are all "As" and they can be integrated through technical means to make a film more adaptable to the functional requirements of different scenarios.

Here are some majority of definitions of “As”:

- Anti-Glare

The principle of Anti-Glare coating is mainly to scatter reflected light by creating tiny rough structures on the surface of the film, thereby reducing direct reflection of light, increasing diffuse reflection, and achieving an anti-glare effect. This coating technology can improve the readability of the screen in a strong light environment while providing a writing and drawing experience closer to paper.

The materials used for AG coatings usually include but are not limited to the following:

- Nano-materials: such as silicon dioxide (SiO2), etc., by adding nanoparticles to the coating to form surface roughness and increase diffuse reflection.

- Polymer materials: such as water-based polyester resins, water-based silicone-modified polyester resins, etc., these materials can provide wear resistance and improve the optical properties of the coating.

- Core-shell structured inorganic particles: through a special core-shell structure design, such as polyethersulfone encapsulating silica, and then quaternary ammonium modification, to improve the dispersibility and wear resistance of the coating.

- Polysaccharide polymers: such as cellulose, starch, chitosan, alginate, etc., these materials have good film-forming properties and biocompatibility and can be improved by chemical modification or adding nanofillers to improve water vapor barrier properties.

Why You Need an Anti-glare Screen & How It Works - Lenovo

* Anti-Glare

- Anti-Fingerprint

The principle of anti-fingerprint coating is mainly based on coating a layer of special chemical materials on the surface of the paper texture film to reduce the surface energy. It makes fingerprints, oil stains, and other dirt difficult to adhere to, and users can clean them easily. AF coating improves the cleanliness and user experience of the screen by reducing the adhesion of fingerprints and oil stains.

The materials used for AF coating usually include:

- Organic silicon and organic fluorine materials: These materials have low surface energy and can provide good anti-fouling performance. In particular, fluorine-containing materials, such as -CF3 groups, provide excellent anti-fingerprint and anti-fouling effects due to their extremely low surface energy.

- Self-limiting surface reaction film layer: After contacting the surface of the material, the surface reaction groups of this type of material react chemically with the surface functional groups to produce chemical bonds and form a film layer. This film layer is usually used on the surface of materials such as glass, anodized, and metal.

- Curable resin film: This type of film layer forms a protective film after curing to provide the anti-fingerprint effect.

The preparation process of AF coating usually includes:

- Evaporation coating: Use an optical vacuum evaporation coating machine to evaporate and deposit the AF material on the surface of the paper-like film.

- Chemical vapor deposition (CVD): A layer of AF material is deposited on the surface of the paper-like film through a chemical reaction.

- Solution coating: The AF material is dissolved in a solvent, and then evenly coated on the surface of the paper-like film by coating, followed by drying and curing.

- Anti-Scratch

The principle of anti-scratch coating is mainly to add a layer of special chemical materials to the surface of paper texture film to improve the surface hardness and wear resistance, thereby resisting scratches and wear. This coating usually contains a hardener, which can form a strong protective layer to reduce the damage of the paper-like film surface by external objects.

The materials used for AS coating usually include:

- Hardened resin: such as polyurethane acrylate, which can form a hard protective layer after curing to improve the scratch resistance of paper-like film.

- Nanoparticles: such as silica (SiO2) or aluminum oxide (Al2O3) particles, which can increase the hardness and wear resistance of the coating.

- Fluoride: Fluoride can provide a low friction coefficient and excellent chemical stability, which helps to improve the scratch resistance of paper texture films.

- Silicone compound: Silicone material has good wear resistance and flexibility, which can improve the durability of paper-like film.

In practical applications, the preparation process of AS coating may involve ultraviolet light curing (UV curing) technology, which is a fast and efficient method to quickly cure the coating material by ultraviolet light irradiation to form a hard protective layer. This coating not only improves the scratch resistance of the paper texture film but also maintains the clarity and touch sensitivity of the paper-like film.

- Anti-Reflective

The principle of anti-reflective coating is mainly based on the interference phenomenon of light to reduce the reflection of light, thereby improving the transmittance and optical performance. The working principle of AR coating is to deposit one or more layers of thin film materials with specific optical properties on the surface of paper-like film, and accurately control the thickness and refractive index of the coating layer so that destructive interference occurs between the reflected light waves, that is, the reflected light waves cancel each other out, thereby minimizing the intensity of the reflected light and increasing the intensity of the transmitted light.

The materials used for AR coating usually include but are not limited to the following:

- Silicon dioxide (SiO2): It has a low refractive index (about 1.45) and excellent transparency. It is mainly used to reduce the reflection of visible light and near-infrared bands. It is widely used in lenses, displays, and optical windows.

- Titanium oxide (TiO2): It has a high refractive index (about 2.4) and is often used in high refractive index layers in multi-layer AR coatings, effectively increasing the interference effect, thereby further reducing the reflectivity.

- Indium tin oxide (ITO): A transparent oxide with conductivity, widely used in optical components that require conductive properties, such as touch screens and solar cells. ITO coating can not only provide the anti-reflection effect but also provide a transparent conductive layer for the device.

In addition, the preparation process of AR coating may involve a variety of methods, including:

- Physical vapor deposition (PVD): The material is converted into a gas phase and deposited on the substrate by physical method, which is often used for AR coating.

- Chemical vapor deposition (CVD): The gas phase precursor is converted into solid film and deposited on the substrate by chemical reaction, which is suitable for preparing high uniformity and high purity AR coating.

- Ion beam coating: The substrate is bombarded with a high-energy ion beam generated by an ion source to deposit a thin film on the substrate, which can significantly improve the density and uniformity of the coating layer.

Custom AR Coatings | Reduce First Reflection Losses

* Anti-Reflective

4. What Related Products are on the Market?

- “A”

Single coating is the most common type on the market. Usually, they focus on the coverage effect of a certain coating, which we call 1A. Some manufacturers will choose to overlay another or two other coatings and claim that they have 3A effects. However, the technology of fusing the coatings, adhering to each other, and playing a full role requires R&D costs and high production costs. The coating directly covered cannot achieve 1+1≥2 but 1+1=1.5 or even lower. Of course, there are also 1A professional-grade products specially made for special needs, such as film-making, Fixed screen displays, etc. For most consumers, this single-coated product can hardly meet the needs of daily multi-scenario use.

- “3A”

First, we have to understand what the 3A paper texture film is. The concept of 3A paper texture film refers to a screen protective film with anti-glare, anti-fingerprint, and anti-scratch properties. This protective film not only provides a writing feel similar to paper but also effectively reduces glare and fingerprints while protecting the screen from scratches. In the market, 3A paper texture films are positioned in the high-end product line, mainly for professional users who need to write and draw frequently, such as designers, artists, and students.

* 3A layer structure

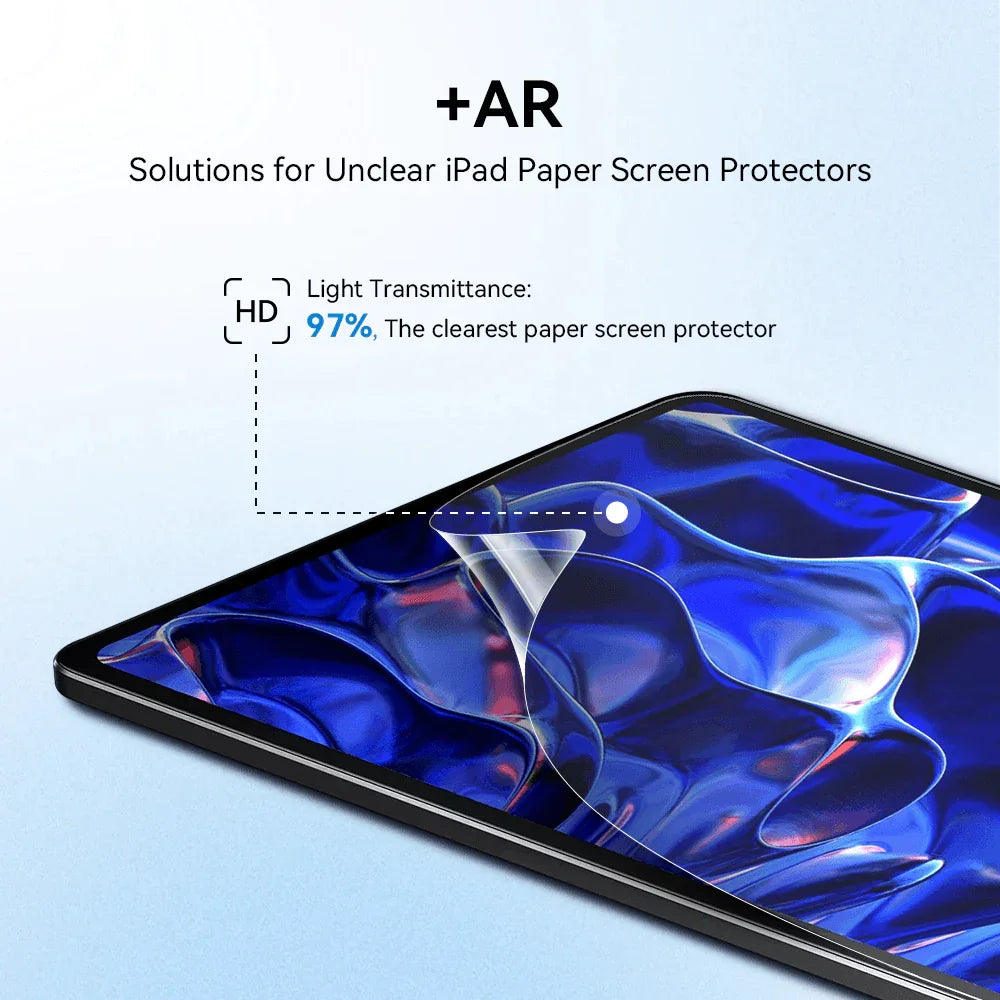

- “AR”

AR paper texture film is one step further. It is named anti-reflective coating (AR Coating), which is a technology that deposits one or more layers of thin film materials with specific optical properties on the surface of optical elements to reduce the reflection loss of light and improve transmittance and optical performance. The main goal of AR paper film is to reduce the light reflection at the interface, thereby increasing the light intensity passing through the optical element to achieve strong light visibility. There is no unified definition for the full name of AR material, because it refers more to a functional property rather than a specific chemical name. In the application of screen protectors, AR materials may involve a variety of different chemical materials and technologies to achieve the anti-reflective effect.

* AR coating layer structure

In the development of screen protectors, AR materials emerged to provide a better visual experience, reduce screen reflections, and improve screen readability. Protective films made of this material are generally more popular than traditional PVC or PET materials because they provide better optical performance and user experience. AR screen protectors achieve anti-reflection effects by adding special coatings to the surface of the protective film, such as multi-layer stacked thin film interference layers. This technology can effectively reduce the interference of ambient light and improve the clarity and contrast of the screen, especially in strong light environments.

This material protective film is widely used in display cover plates, camera lenses, solar panels, and front and rear windshields of electronic devices such as smartphones and tablets. The positioning of AR paper film in the market is to provide a clearer visual experience and higher screen protection performance, especially suitable for users with high requirements for screen display effects.

5. What are the Upgrades of AR Compared to 3A ?

Compared with 3A paper film, the upgrade of AR paper film is mainly reflected in the following aspects:

- Higher light transmittance: AR-type paper film can provide higher light transmittance through multi-layer thin film interference technology, reduce screen reflection, and make the screen display clearer, especially in a strong light environment.

- Better visual experience: Due to the high light transmittance and anti-reflection properties of AR-type paper film, it can provide a visual experience closer to the naked screen, suitable for users who pursue high-definition display effects.

- Abrasion resistance: AR-type paper film is usually made of more wear-resistant materials, which can provide a longer service life while maintaining a good writing and drawing experience.

- Suitable for a variety of scenarios: AR-type paper film is not only suitable for writing and drawing but also very suitable for watching videos, reading, and playing games, because it can provide a clearer visual experience.

6. Conclusion

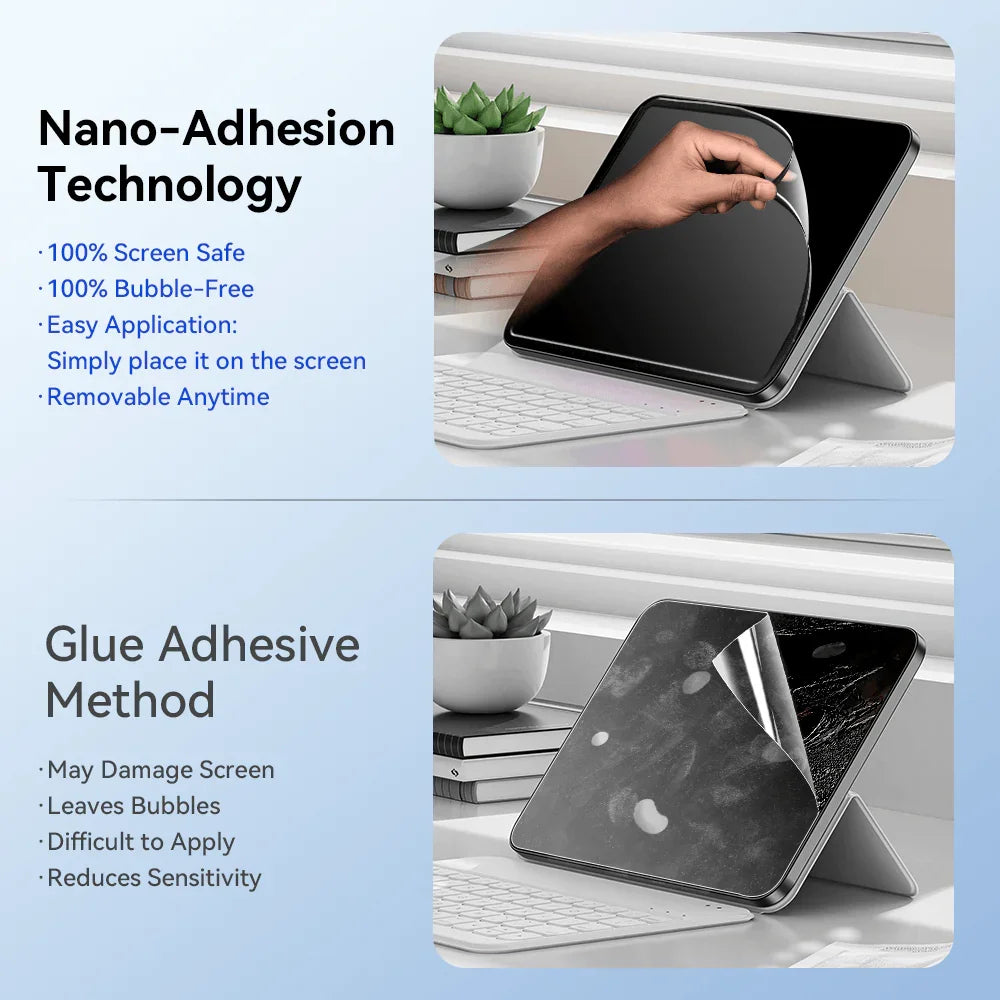

1A-2A coated paper-like films (strictly speaking, coatings, not low-quality production and false propaganda of fake 2A-3A) are basically the most common varieties on the market. Such products are usually low-priced and cannot meet the needs of users for good use.

There are not many 3A paper-like film products because they are relatively expensive and the initial experience is difficult to differentiate from fake 3A (the difference can be found after long-term use).

The latest AR-structured 4A-level paper-like film products are even rarer, and they basically meet all the needs of users. The reason for their small number is whether the brand can own the relevant patents and technologies. Only with these elements can the brand convey products with appropriate prices.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.